Hexagon Measurement SystemsNo matter what Hexagon measurement equipment or software you use, we want to hear your ideas and suggestions on how we can improve.

Thanks for your assistance in helping us shape the future. |

|

New point construction method: "high point"

New point construction method: "high point"

Finding the "high point" of a feature or scan is a very common measurement task.

In pc-dmis, this is a complex task, that requires an understanding of array indexing, and significant manual entry into a generic feature. It is prone to error, is very time consuming, and for users never exposed to a programming language it's a complete non-starter.

A simple, interface-based point construction method could be added to address these issues. The new method should be based on the DMIS method "CONST/EXTREM". It is very complete, and since pc-dmis imports DMIS code - it only makes sense to have a 1 to1 mapping of the DMIS definition.

Add a length and width spacer option for auto planes

Add a length and width spacer option for auto planes

Currently PC-DMIS has a square spacer that can be set for auto planes. It would be nice if we could specify the length and width of the spacer

Basic Dimension option

Basic Dimension option

How about a Basic Dimension option, in the Location Tool Box. That way the basic dimensions don't need to have tolerances.

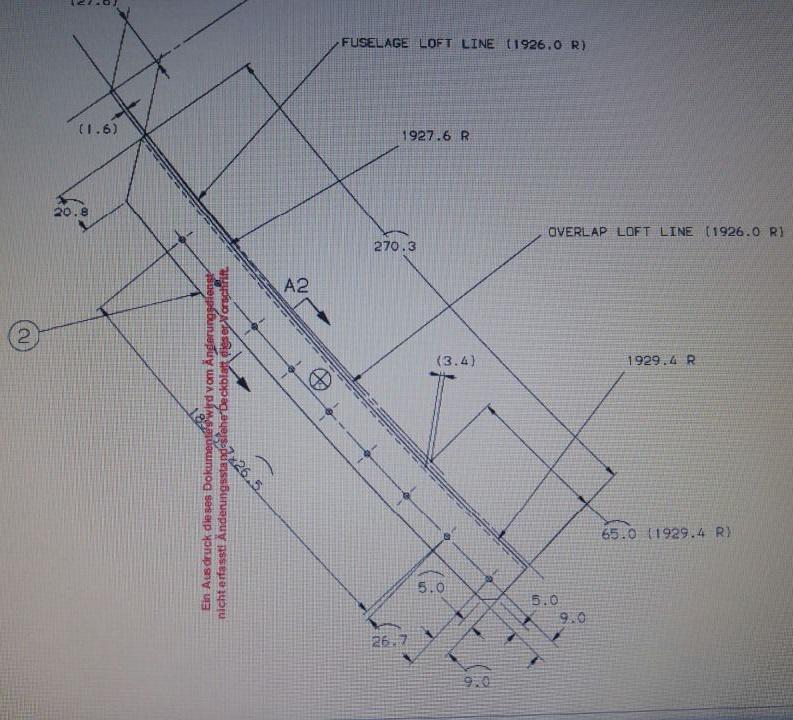

Angular Length Reporting

Angular Length Reporting

Maybe there is an easy way to report it ;if we have either a check box on the location (angle between) dialog window like "from formula" or an easier assignment set will be great.

Maybe there is an easy way to report it ;if we have either a check box on the location (angle between) dialog window like "from formula" or an easier assignment set will be great.

Here is the code in order to report it :

CIR1 =FEAT/CIRCLE,CARTESIAN,OUT,LEAST_SQR

THEO/<98.516,-145.613,-2.547>,<0,0,1>,506.5,0

ACTL/<98.516,-145.613,-2.547>,<0,0,1>,506.5,0

MEAS/CIRCLE,4,ZPLUS

HIT/BASIC,NORMAL,<51.696,103.272,-2.55>,<-0.1848771,0.9827616,0>,<51.696,103.272,-2.55>,USE THEO=YES HIT/BASIC,NORMAL,<99.287,107.636,-1.309>,<0.0030416,0.9999954,0>,<99.287,107.636,-1.309>,USE THEO=YES

HIT/BASIC,NORMAL,<166.819,98.253,-3.669>,<0.2697032,0.9629435,0>,<166.819,98.253,-3.669>,USE THEO=YES

HIT/BASIC,NORMAL,<227.698,72.212,-2.661>,<0.5100969,0.8601169,0>,<227.698,72.212,-2.661>,USE THEO=YES

ENDMEAS/

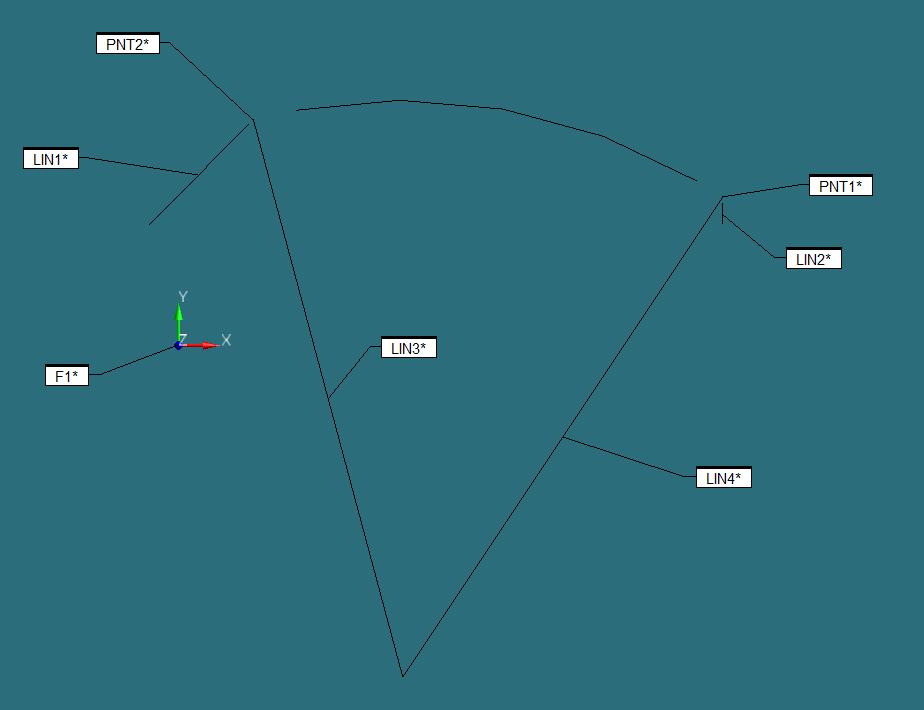

LIN1 =FEAT/LINE,CARTESIAN,UNBOUNDED

THEO/<31.03,97.103,-1.56>,<-0.7071068,-0.7071068,0>

ACTL/<31.03,97.103,-1.56>,<-0.7071068,-0.7071068,0>

MEAS/LINE,2,ZPLUS

HIT/BASIC,NORMAL,<31.03,97.103,1.086>,<-0.7071068,0.7071068,0>,<31.03,97.103,1.086>,USE THEO=YES

HIT/BASIC,NORMAL,<-13.352,52.72,-4.207>,<-0.7071068,0.7071068,0>,<-13.352,52.72,-4.207>,USE THEO=YES

ENDMEAS/

LIN2 =FEAT/LINE,CARTESIAN,UNBOUNDED

THEO/<239,62.251,-5.264>,<0,-1,0>

ACTL/<239,62.251,-5.264>,<0,-1,0>

MEAS/LINE,2,ZPLUS

HIT/BASIC,NORMAL,<239,62.251,-5.016>,<1,0,0>,<239,62.251,-5.016>,USE THEO=YES

HIT/BASIC,NORMAL,<239,53.115,-5.512>,<1,0,0>,<239,53.115,-5.512>,USE THEO=YES

ENDMEAS/

PNT1 =FEAT/POINT,CARTESIAN,NO

THEO/<239,65.1,-5.264>,<0,-1,0>

ACTL/<239,65.1,-5.264>,<0,-1,0>

CONSTR/POINT,PIERCE,CIR1,LIN2

PNT2 =FEAT/POINT,CARTESIAN,NO

THEO/<32.922,98.995,-1.56>,<-0.7071068,-0.7071068,0>

ACTL/<32.922,98.995,-1.56>,<-0.7071068,-0.7071068,0>

CONSTR/POINT,PIERCE,CIR1,LIN1

LIN3 =FEAT/LINE,CARTESIAN,UNBOUNDED,NO

THEO/<98.516,-145.613,-2.547>,<-0.259008,0.9658673,0.0038973>

ACTL/<98.516,-145.613,-2.547>,<-0.259008,0.9658673,0.0038973>

CONSTR/LINE,BF,3D,CIR1,PNT2,,

OUTLIER_REMOVAL/OFF,3

FILTER/OFF,WAVELENGTH=0

LIN4 =FEAT/LINE,CARTESIAN,UNBOUNDED,NO

THEO/<98.516,-145.613,-2.547>,<0.5546916,0.8319869,-0.0107257>

ACTL/<98.516,-145.613,-2.547>,<0.5546916,0.8319869,-0.0107257>

CONSTR/LINE,BF,3D,CIR1,PNT1,,

OUTLIER_REMOVAL/OFF,3

FILTER/OFF,WAVELENGTH=0

DIM ANGL1= 2D ANGLE FROM LINE LIN4 TO LINE LIN3 ,$

GRAPH=OFF TEXT=OFF MULT=10.00 OUTPUT=BOTH

AX MEAS NOMINAL +TOL -TOL DEV OUTTOL

A 48.703 48.703 0.010 0.010 0.000 0.000 ----#----

ASSIGN/V1=((2*3.14*CIR1.R.MEAS)/360)*ANGL1.A.MEAS

F1 =GENERIC/NONE,DEPENDENT,CARTESIAN,OUT,$

NOM/XYZ,<0,0,0>,$ MEAS/XYZ,<0,0,0>,$

NOM/IJK,<0,0,1>,$

MEAS/IJK,<0,0,1>,$

RADIUS/0,0,$

ANGLE/215.5,V1,$

DISTANCE/0,0

DIM LOC1= LOCATION OF PLANE F1 UNITS=MM ,$

GRAPH=OFF TEXT=OFF MULT=10.00 OUTPUT=BOTH HALF ANGLE=NO

AX MEAS NOMINAL +TOL -TOL DEV OUTTOL

A 215.160 215.500 0.500 0.500 -0.340 0.000 -#-------

END OF DIMENSION LOC1

Allow Max & Min Index of Polar Radius from a scanned feature

Allow Max & Min Index of Polar Radius from a scanned feature

When finding a high point of a linear feature it's possible to use the Maxindex assignment relative to a specific axis. For example "maxindex(scan.x)". This will return the max value in X for that scan.

When scanning radial features and finding a max Polar Radius, one would expect to use "maxindex(scan.PR)" to return the max value for PR in that scan. Thus giving a high point of a radius for example.

This command doesn't work with polar radius.

Save the PC-DMIS version/SP/Schema so that we can identify what version of PC-DMIS is needed to open this file.

Save the PC-DMIS version/SP/Schema so that we can identify what version of PC-DMIS is needed to open this file.

Can we get some way to record what version/schema of PC-DMIS is required to open a particular PC-DMIS file? With the rolling cutoff and some users having a mix of schema for their routines, I fear difficulties with using the migration utilities in the future.

Add UPR as smart parameter in the measurement strategy editor

Add UPR as smart parameter in the measurement strategy editor

As more and more customers are asking us to scan (with a probe) all features, they also got their standards for using the filters in scanning. In those standards, they also ask for a specific UPR which relates to the current diameter. For example, Ø8 and smaller require a UPR setting of 15. Ø8-Ø25 require UPR 50 etc.

I'd like to add this as a smart parameter in the Measurement Strategy Editor to make sure we also use the correct settings.

AUTO PLANE RINGS

AUTO PLANE RINGS

I would like to see an option where we can adjust the distance between multiple rings when checking a radial auto plane. We of course have the option to adjust the size of the rings but, to my knowledge, don't have the option to adjust the distance between.

Comment Box Update!

Comment Box Update!

I think the Comment box could use some help. I've been using PCDMIS since the 2014 version and its basically untouched in 10 years. As an offline programmer, the comments are sometimes the only way I can communicate to the inspection operators.

I have seen some people on here asking for Font Types and Colors, and i think that's a really great idea!

I would also like to see more ALT codes translated correctly to the comment box, or maybe add more than the four symbols at the bottom of the Comment Text Box. GD&T uses so many different symbols to communicate there should be a library to choose from when typing out or operator comments.

Even as I type this out, I'm looking at the options i have to edit my text and I would love to see something similar to this woven into the comment section of PCDMIS. (see below)

Possibility to disable automatic highlighting of the feature on which the cursor is located

Possibility to disable automatic highlighting of the feature on which the cursor is located

There should be an option to disable automatic highlighting of a feature on which the cursor is placed.

When programming, the large shadow of the highlight can interfere. Especially with single circles this is a disadvantage.

At the moment there is only the possibility to change the color of the highlight.

Customer support service by UserEcho