Hexagon Measurement SystemsNo matter what Hexagon measurement equipment or software you use, we want to hear your ideas and suggestions on how we can improve.

Thanks for your assistance in helping us shape the future. |

|

Easy way to populate results in excel based first article travelers

Easy way to populate results in excel based first article travelers

Looking for a way to populate results in specific custom order in Excell based first article travelers.

Create Straight Tube Project

Create Straight Tube Project

Crazy as it sounds, but we do have straight tubes that we measure too, some with flanges or fittings at the ends. I know that there is the toolbox to measure a straight, but it is limited to just a straight. Would like to be able to create and inspect a straight tube with or without flange profiles and check for the deviations.

Allow tolerance warning threshold to be configured

Allow tolerance warning threshold to be configured

UK customer has requested a way in Inspect to specify a % of tolerance, and if dimensions are within tolerance, but above the % of tolerance, they would be marked in yellow on the dimension summary screen at the end of execution.

Modification of the Protocol Header / Customer Request

Modification of the Protocol Header / Customer Request

We need more Variables ind the Header of the Protokoll.

The Customers need to insert.

1. Customer

2. Part

3. Controller

4. Tube Material

5. Bender

6. Comments

7. ...etc.

See CAD model inside Inspect Interface.

See CAD model inside Inspect Interface.

Would like to be able to view the CAD model within the Inspect user interface while the program is executing. Similar to the current Operator mode functionality.

Remembering past measurements

Remembering past measurements

Now PC-DMIS remembers only measurements made on the last part. A lot of time I need a complete data of part that was measured in past. It could be set to remember last xx measured parts. I know that Calypso has this feature.

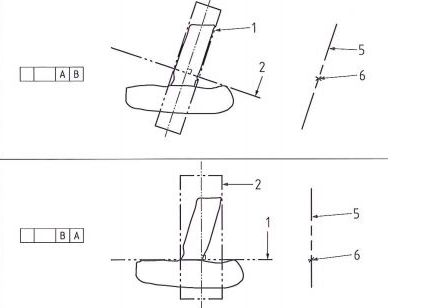

DRF feature construction option(s) - relative to other features/datums

DRF feature construction option(s) - relative to other features/datums

Add options to construct Datum features in such a way that they reflect the standard.

Example - Datum A is a Plane, and Datum B is a cylinder bore nominally perpendicular to the plane.

As per both ISO and ASME standards, Datum B would be a Max Insc Cylinder Perpendicular to Dat A.

It's easy enough to construct a Max Insc cylinder, but this wouldn't be forced perpendicular to the plane, currently you'd have to measure it as a series of circles, then construct a Max Insc Circle in the correct workplane after levelling to Dat A.

See bottom image for example (image shows shaft not bore but principle is the same).

Like wise construct a datum plane from a measured plane relative to another feature (Top image)

Make it possible to re-enumerate feature numbers after program is written/edited.

Make it possible to re-enumerate feature numbers after program is written/edited.

Your program is finished but some points or features were added and their out of numerical order.

A Re-number feature would put them all in ascending order.

Program Single Block Mode

Program Single Block Mode

It would be nice to see an addition of a 'single block' mode, similarly to CNC machines where you can step through each line/block of code one at a time. This would be good for proving out program or certain sections of programs. This would be better than having to CTRL+E each line to make sure things dont crash.

Adding a single block toggle to the execution popup window while executing would have the user click the play button/green button on the jogbox to advance each block.

Have the clearance cube wrap around the form of the part instead of a cube that has deadspace in it

Have the clearance cube wrap around the form of the part instead of a cube that has deadspace in it

This would save lots of time for some parts. Think of it like the shield from the Dune movies. The clearcube should form around the part

Servicio de atención al cliente por UserEcho