Hexagon Measurement SystemsNo matter what Hexagon measurement equipment or software you use, we want to hear your ideas and suggestions on how we can improve.

Thanks for your assistance in helping us shape the future. |

|

Inspect Pallet Playlist add multiple pallets with spacing controls

Inspect Pallet Playlist add multiple pallets with spacing controls

Many customers have large enough machines and smaller parts facilitating the ability to load multiple fixtures on the machine. It would be helpful to have the ability to specify spacing between fixtures to execute sequentially.

This could possibly be done with fixture alignments rather than spacing for provision where the spacing may not be uniform.

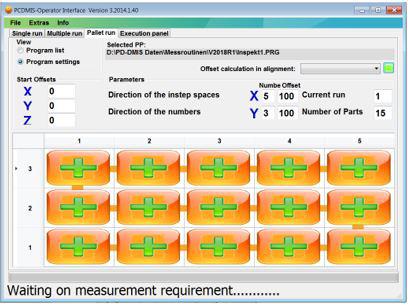

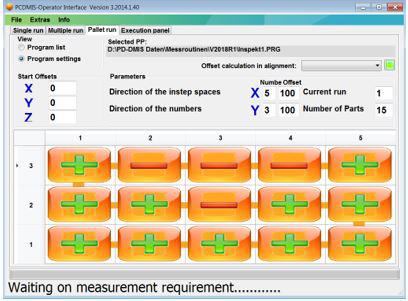

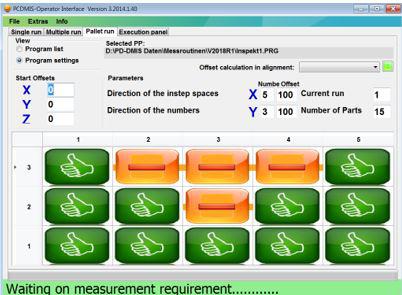

Pallet Run with Inspect

Pallet Run with Inspect

It would be great, if we have the possibility to do the “pallet Run” with Inspect – like Operator Interface.

Just enter the number of the parts and their offset and let’s go.

If a part does not exist, just uncheck it.

Don't close PC-DMIS on closing INSPECT if PC-DMIS was already started before INSPECT

Don't close PC-DMIS on closing INSPECT if PC-DMIS was already started before INSPECT

It's a bit irritating that INSPECT always closes PC-DMIS when closing, even when PC-DMIS was already started before INSPECT.

This may not be a real problem for end users, only for those that run a lot of tests of different things...

I would like to see the Live Image view so I can use INSPECT on a vision machine, and use the view to do the manual alignment features

I would like to see the Live Image view so I can use INSPECT on a vision machine, and use the view to do the manual alignment features

At the moment, INSPECT is not very useful for Vision machines, as without seeing the camera view, then the manual alignment features are impossible to position.

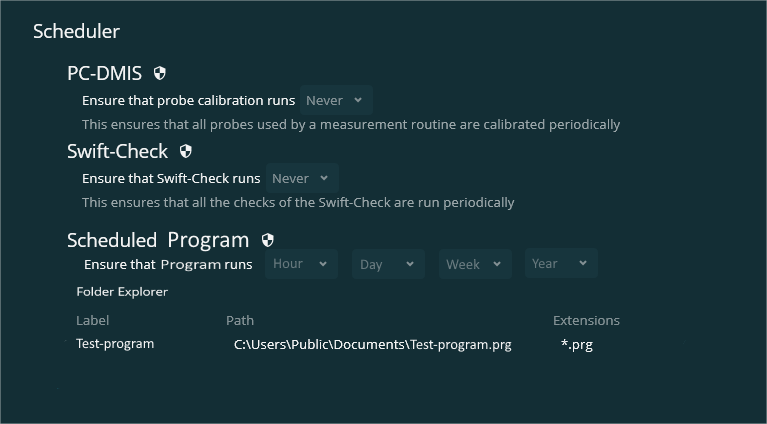

Schedule program

Schedule program

In inspect 5.1 we have been given the opportunity to schedule a calibration or Swift check. could it be possible to extend the "schedule" function so it becomes possible to schedule a specific program to run every hour, day, week or year.

see example:

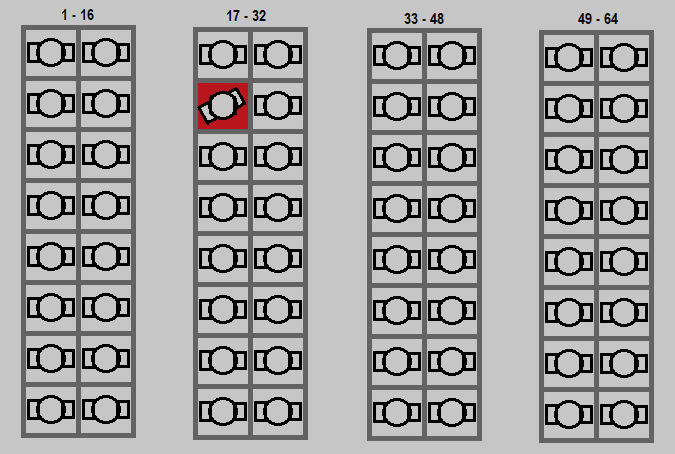

Allow serial number for each pallet cell to be scanned on barcode

Allow serial number for each pallet cell to be scanned on barcode

In Inspect, the serial numbers (or other trace) can be entered in the pallet screen prior to measurement.

It would be useful to have an option where the serial number for each cell could be scanned in using barcode, to make this process more efficient and less error prone

Filed on behalf of a customer.

Have the possibility to store the settings of Inspect on network

Have the possibility to store the settings of Inspect on network

Inspect users with multiple CMM's - and who want to have the same settings (playlists, tracefields et cetera) on all the stations - are storing these settings locally on every station. This is time consuming every time they update the playlist and tracefields. Users need to update every station in this case and they loose a lot of time and make possibly erros.

It would be nice if Inspect users can store these settings on the network drive, so that you can change the playlists and tracefields from your offline station and then all your other Inspect stations are up-to-date.

Make an option in Inspect to have the barcode in Inspect linked to a COM port

Make an option in Inspect to have the barcode in Inspect linked to a COM port

When you have the barcode option linked to a COM port, then it always checks if there is an input from the barcode reader. Even if you're not in the input field for Inspect. With the link to a COM port, you are always sure that the routine starts.

Currently there is a hardware keyboard wege and sends the input from the barcode reader to the keyboard. It would be nicer if there is a software keyboard wedge. A software keyboard wege connects directly to the COM port and not the keyboard. Data from the barcode scanner is sent to the COM port and is rerouted to the keyboard buffer. This way you're sure that Inspect is always reading the input from the barcode scanner even if you're in another input field.

Inspect Pallet execution cell failure unexpected hit or probe missed part error handling and continuation.

Inspect Pallet execution cell failure unexpected hit or probe missed part error handling and continuation.

Add possibly two modes of error handling whenever a cell part is not fixtured correctly.

1. Advance to next cell and keep all index/counter trace fields sequenced correctly to cell. This would be best for operator environments.

Allow only the bad cells to then be rerun after correction maintaining trace field sequence as noted.

As they can currently select cells for execution, the trace field sequence is the the important piece.

Also, if they are running successive fixtures, allow for control of Index/counter trace inputs, stop start or override with specific cell value.

2. Create or use existing notification tools to text programmer, or set stack/message light status to raise awareness.

Allow programmer to reset poorly fixtured part and resume execution from that cell maintaining trace sequence as previously stated.

Multiple sequential playlist execution with index counter trace field sequencing.

Multiple sequential playlist execution with index counter trace field sequencing.

This appears to be similar to one Lupe added previously.

In lieu of a multi-fixture sequential execution, provide a means of controlling count and/or prompting for next fixture load. Also, it would be important for index/counter trace fields to be sequence with fixture/cell.

Servicio de atención al cliente por UserEcho