Hexagon Measurement SystemsNo matter what Hexagon measurement equipment or software you use, we want to hear your ideas and suggestions on how we can improve.

Thanks for your assistance in helping us shape the future. |

|

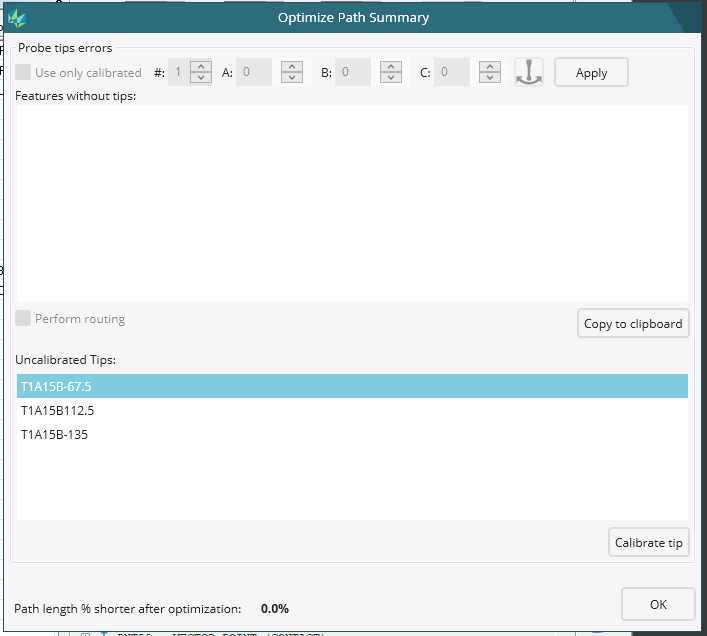

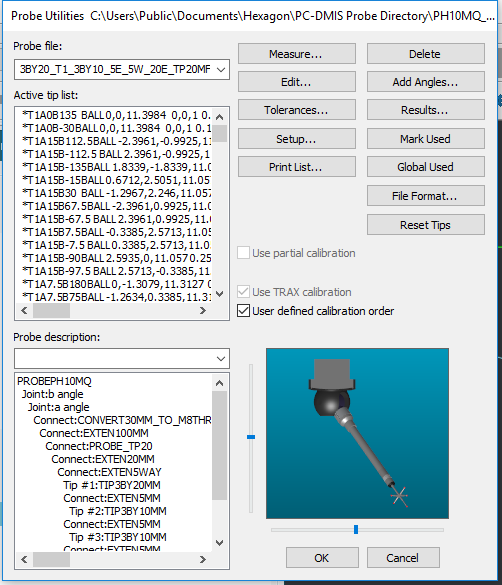

Optimize Path Summary Uncalibrated Tips

Optimize Path Summary Uncalibrated Tips

Optimize Path Summary will show a list of Uncalibrated Tips. Uncalibrated tips list shows all the uncalibrated tips used by the optimization. You can click on a tip and click Calibrate tip to open the Probe Utilities dialog box and calibrate the uncalibrated tips.

-

The problem is that the Tip that is selected in the Uncalibrated tips list will not be Highlighted in the Probe Utilities dialog box Active Tip list.

-

Selected the Uncalibrated Tip.

Selected Calibrate tip. Now Enjoy your search.

In the past a report window could be updated while program was running, now it doesn't...why?

In the past a report window could be updated while program was running, now it doesn't...why?

Report window update while program is ruynning

Show probe ball button

Show probe ball button

Hi,

The the show probe button in graphic Item toolbar was a very useful buton. So thanks for developers! And I suggest more button: Show only the probe ball button.

Many times I want to check visual the gap between the ball and the part and so many times the shaft of the last item(probe) hide all things what I want to see...

elements on a flat not visual

elements on a flat not visual

I have many big parts with many elements to check.

The biggest problem, what I have, is when I set the elements on a flat (when this are shading) I can´t see this from all positions.

Can you make the flat transparent or the elements just like to shape, that we can see all elements on a flat in al positions?

Multiple CAD Views and Origin Axis on Reports

Multiple CAD Views and Origin Axis on Reports

This would help with our customers to better understand our data and our benders to understand what adjustments need to be made in process.

Have the ability to calculate area accurately.

Have the ability to calculate area accurately.

I'd like the ability to calculate the area between 2 somewhat concentric circles, or even irregular shaped features and dimension that area.

your measurements

your measurements

hello

I think it would be nice if you can see during your measurements whether something is right or wrong in enspect.

XACT PROFILE

XACT PROFILE

With legacy dimensioning, in the profile dimension box you could highlight all the features you wanted and when you hit create it would create an individual dimension for each feature. With XACT dimensioning it produces a feature set and one dimension shows on the report. Can you make it to where you could have the option of grouping the features into a feature set or have the option to mass create individual dimensions for each feature instead of having to choose each feature one at a time and hitting create?

Animated probe changer

Animated probe changer

since the animated machines are included with the pcdmis software, shouldnt the animated probe changer be included as well? Apparently this is a paid addon currently, but would be handy for offline path movement and collision detection.

SQ Inspect 3.1 - Clear password field when user name field is cleared or typed over

SQ Inspect 3.1 - Clear password field when user name field is cleared or typed over

Using SmartQuality Inspect 3.1 (install set from PCDMIS 2018 R1)

The password field is not getting cleared if a user clears the user name to enter a new one or types over it. I happen to have two SmartQuality users with the same password.

I can logout from one and actually type the other username and the password

field is still there uncleared from last user login. Press sign in and I am logged in.

We must clear the password field if anything is done to the user name one.

Customer support service by UserEcho