Hexagon Measurement SystemsNo matter what Hexagon measurement equipment or software you use, we want to hear your ideas and suggestions on how we can improve.

Thanks for your assistance in helping us shape the future. |

|

Ability to adjust the vector of an avoidance move

Ability to adjust the vector of an avoidance move

In addition to being able to separately adjust the distance of avoidance moves, it would be nice to control the vector of an avoidance move.

CREATING A WIDTH AUTOMATIC USING THE AUTO SLOT MEASURMENT

CREATING A WIDTH AUTOMATIC USING THE AUTO SLOT MEASURMENT

If I can create a slot or a circle relative to a plane than why can't I create a width in the same manner. Why should I have to create additional alignments. Example: I have a project that has 60 slots most of which are used as datum features. Creating 120 widths and 60 additional alignments in a program is not practical. Secondly, Why can't I use the points that make up the auto slot measurement and have pcdmis create widths using those points automatically ? Something else to consider is that all of these slots are drafted with no parallel sides.

Inserting a feature into an argument list

Inserting a feature into an argument list

Inserting a feature into the beginning or middle of an argument list, PC-DMIS doesn't parse the string as it's pasted and thinks the existing name is getting lengthened, even if a comma is present. When creating a FEAT/SET, I needed to include individual hits. I started with the dialog box and selected PNT3. It needed to be the 3rd point in the list, but it was the easiest to select. The feature set was:

CONSTR/SET,BASIC,PNT3,,

Then I was told I needed to change it so it explicitly brought in the single hit

CONSTR/SET,PNT3.HIT[1],,

Then I needed to add the first 2 points from LIN_L in front of it in the list

CONSTR/SET,BASIC,LIN_L.HIT[1],LIN_L.HIT[2],PNT3.HIT[1],,

But this didn't squeeze 2 additional points in front PNT3. Instead, it changed the name of the single argument to 'LIN_L.HIT[1],LIN_L.HIT[2],PNT3.HIT[1]'. This behaves the same whether I paste the new names as strings, the them manually or use a combination of both.

It appears that PC-DMIS doesn't recognize the commas as delimiters when it's re-parsing the line after an edit. And it doesn't change the quantity of arguments unless the additions are at the end.

excel form report keep the Excels formatting/allow tables.

excel form report keep the Excels formatting/allow tables.

currently Excel form report clears out any formatted cell where the data will generate. Can we have it so it doesn't clear out the cells formatting or so the information will generate in a table inserted into the excel sheet.

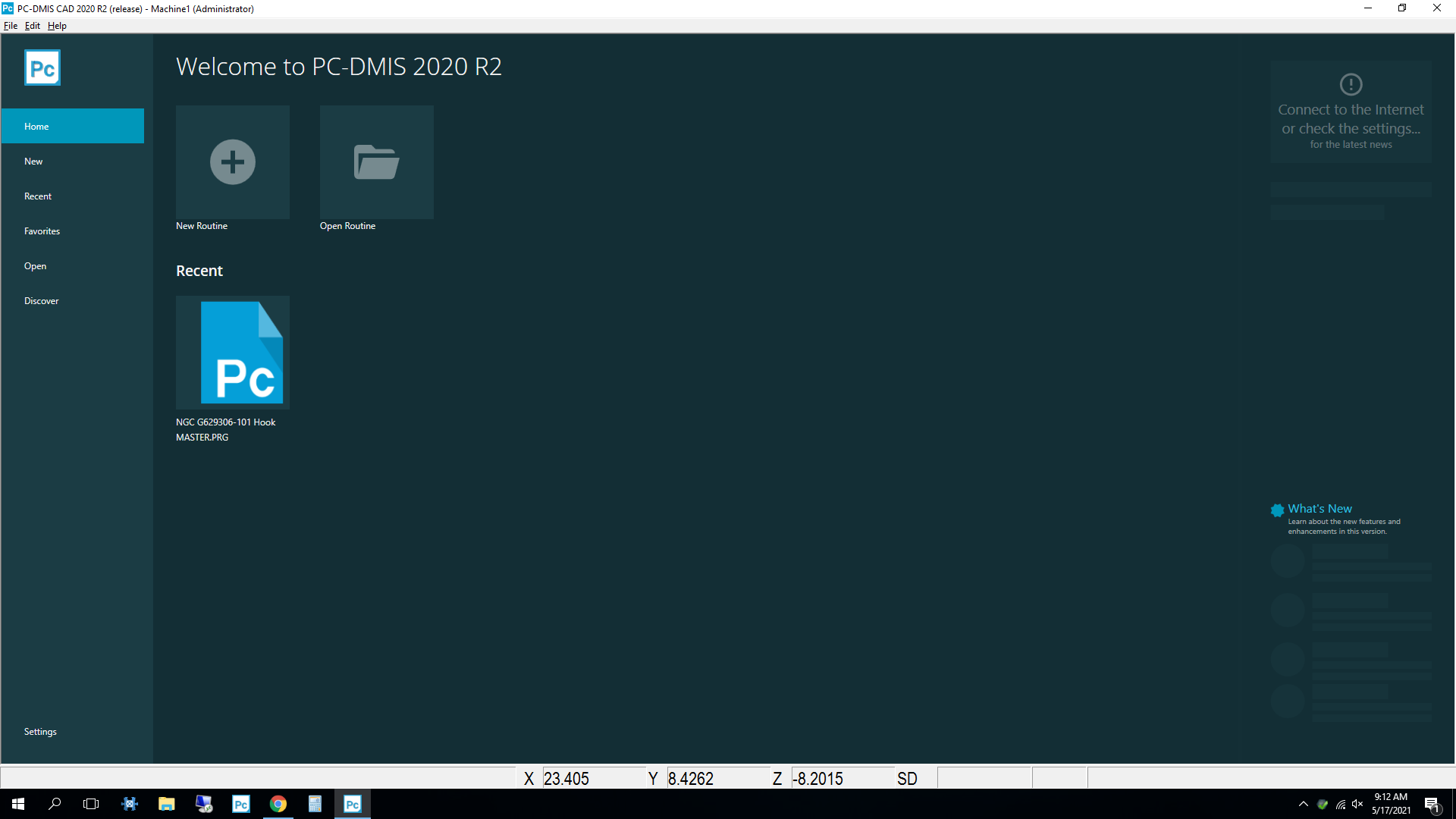

Dark Mode for Programming

Dark Mode for Programming

Hello! I noticed that the latest version of PC-DMIS includes a dark mode feature. It applies to the home page and some options such as GT and setting up your datums inside a program but that is it. I use dark mode for everything when available. When you stare at a screen for over 8 hours a day, the white background for me personally is taxing. I would LOVE to have this feature available for the whole programming screen. Including the grey boxes/windows for features and the options at the top of the screen, and have a dark color scheme for the actual coding as well.

If this color scheme could be for the actual programming side, and it includes a darker color for the grey windows where File and everything is, I would be one happy customer and I'm sure others would be too.

Thanks for taking the time to read my suggestion!

program mode mouse button combo for end feature

program mode mouse button combo for end feature

In program mode, programming on cad, create a mouse button combo that would create the feature instead of having to hit end on the keyboard

Maybe left + right mouse button clicked together

Add functionality in INSPECT and PCDMIS to allow users to update the calibration TOOL to use globally to all probes

Add functionality in INSPECT and PCDMIS to allow users to update the calibration TOOL to use globally to all probes

Not sure a request like this has been filed. Most customers in Medical device, swap the calibration spheres on production CMMs as part of the artifact annual calibration process. A calibrated/certified sphere is placed on the machine and the prior one is sent out for calibration. Process repeats.

The issue if that any and all defined probes on that CMM have to be manually updated (including any Parameter sets) to reflect the new sphere to be used. This a very tedious and prone to error task that requires CMM support personnel.

Would be nice to have a tool in PCDMIS or maybe even INSPECT that allows user to confirm or edit the calibration tool the AUTOCALIBRATE is to use. Or a tool that allows user to Globally update all current probes in the system, or a select list of probe files.

Customers running in Operator mode when clicking on Calibrate probe have no way to validate or specify the tool and this should not be acceptable.

Customers running programs via automation rely on autocalibrate commands. These also do not provide for ways to specify or confirm the tool ID w/o first manually editing every single probe and any parameter sets saved within that probe file.

Customer support service by UserEcho