Hexagon Measurement SystemsNo matter what Hexagon measurement equipment or software you use, we want to hear your ideas and suggestions on how we can improve.

Thanks for your assistance in helping us shape the future. |

|

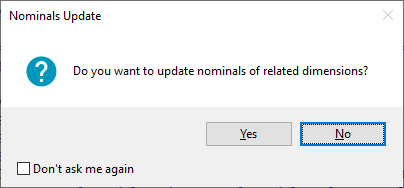

Disable warnings per session

Disable warnings per session

Below is an example of the various warnings

At this moment there is a possibility that you forget you checked the 'Don't as me again' checkbox, and leave a collegae (or yourself) with the possibility to make unwanted recalculations without noticing.

When you make that it only applies for this session (until the program closes) you can make the chance of this error/mistake a bit smaller.

AutoCal Parameter Sets

AutoCal Parameter Sets

I would like to see parameter sets added as a parameter of the PROBEDATA function. I currently use a log file (.csv) to track the calibration of parameter sets of probe tips for different programs.

Currently, one can use the date and time data in a probe file for a particular tip to get information on the last calibration date/time, but there is nothing like that for parameter sets.

Expand Optimize Path to Work with Clearance Planes

Expand Optimize Path to Work with Clearance Planes

As of version 2019, the legacy Optimize Path tool has been removed, and the new Optimize Path (formerly "Preview" as opposed to "Legacy") chokes on MOVE/CLEARPLANE commands. Since clearplane moves can be controlled in the Edit window they are much more versatile than the clearance cube, and for flat parts they are much more efficient than Auto Insert Moves. It should not be hard to make the Optimize Path tool work with clearance planes - please do so!

In PC-Dmis when measuring a cylinder from the outside

In PC-Dmis when measuring a cylinder from the outside

When measuring a cylinder from the outside, a pin, with avoidance on, the probe approaches the center of the cylinder before moving to the first measure point on the outside of the cylinder. This is not a problem unless the center of the cylinder is outside the part and the probe attempts to plunge through the part wall. Please consider changing the routine to apply the avoidance to above the first measured point or add a toggle to allow the user to turn on that option.

Having the option to select a variable as a lighting option instead of a percentage in lighting parameters

Having the option to select a variable as a lighting option instead of a percentage in lighting parameters

For example, in vision, you save lighting settings to percentages you want. I would like to have a setting where I can pick a lighting that I want on with a preset variable. Like Bottom Light = V999. Then the programmer can assign the variable at the top of the program.

So instead of it saying "Bottom Light=<off, 100, on>" it would say "Bottom Light=<off,V999, on>"

Instead of having to manually type this for every feature, it will hold the value as a variable rather than a number. This could potentially solve all lighting issues going forward and make it super easy for a programmer to update/change programs if needed. And if possible

Add a dropdown menu for the contruct feature window

Add a dropdown menu for the contruct feature window

Ad a drop down menu in the construct feature window to select what kind of feature you want to construct.

This makes constructing different feature's easier, and faster.

The function i'm looking for is already in place with the auto feature window, here you could start with a vector point, and then select the drop down menu to change to cylinder.

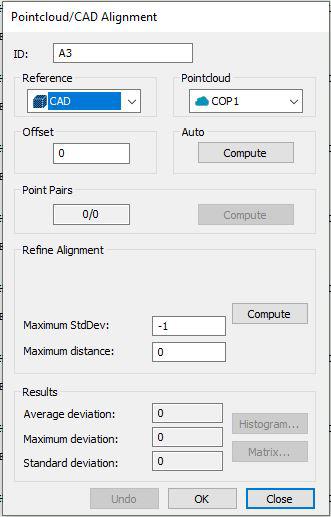

"Manual" Alignment of Pointcloud

"Manual" Alignment of Pointcloud

It would be nice to have the opportunity to manually (by using mouse) align pointcloud to cad model, or one pointcloud to other pointcloud and from here make eventualy refine alignment. Idea is to put with mouse COP on CAD or other COP to lock this on specific area.Thanks to this it would be easier to align only partly scanned surfaces. Today even if I using point pairs sometimes alignment is moving far away from expected place. Actual functionality is working good only if whole part is scanned allround.

خدمة دعم العملاء من خلال UserEcho