Hexagon Measurement SystemsNo matter what Hexagon measurement equipment or software you use, we want to hear your ideas and suggestions on how we can improve.

Thanks for your assistance in helping us shape the future. |

|

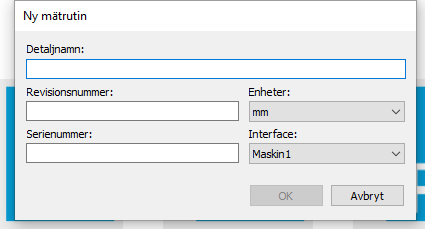

filelocation, new program

filelocation, new program

When I create a new program I want to have the opportunity to chose filelocation for that new program .

Nickname should carry over to report names (uses PRG name currently) in INSPECT

Nickname should carry over to report names (uses PRG name currently) in INSPECT

INSPECT allows for a NICKNAME for the program (Icon) but then in the REPORT section it reverts to the Program name. The operator won't know the program name they will identify with the nickname so the nickname should be used for the reports as well.

Settings window, probe tab, display "fastprobemode" status

Settings window, probe tab, display "fastprobemode" status

Under VIEW|OTHER WINDOWS|SETTINGS WINDOW

the tab in the settings window dialog "Probe", should have a notification area for "FastProbeMode" status at current cursor position in the edit window. Either "on", or "off".

Select new workplane and adjust graphic display window.

Select new workplane and adjust graphic display window.

Create a new setting that will allow the graphic display window to rotate and center to a new workplane whenever it is selected from the settings workplane dropdown.

Restore settings .

Restore settings .

I would like to have oppotunity to save my settings. Menylayout, shortcuts, file locations and so on stored outside PC demis. So you can restore all settings by using this file to restore all settings after an update.

Extreme Point

Extreme Point

When constructing an extreme point on a feature that has been created using a series of points, PC-DMIS creates the point by selecting the point of the series that is in the extreme direction that you have selected. This however is usually not the extreme point of the feature. Can PC-DMIS calculate and construct the point at the true extreme of the feature?

Allow Inspect slideshows to handle dimensions created within loops

Allow Inspect slideshows to handle dimensions created within loops

Within Inspect, we are not able to add multiple dimensions to slideshows if they are created within a loop. The dimension is able to be accessed via arrays within PC-DMIS, however Inspect does not allow me to do this.

Example:

I loop through 10 parts, and within the loop I am dimensioning the diameter of each part as a location feature called "DIAMETER". In Inspect, I would like my slideshow that shows the DIAMETER dimension to update for each part in the loop, but currently it only displays the DIAMETER feature for part 1 (loop 1) and it stays static during the rest of the runs.

ADD easier alignment with offset holes in alignment window

ADD easier alignment with offset holes in alignment window

add offset boxes in alignment window instead of having to compute the angle or add code to alignment

Automatically save program after run

Automatically save program after run

PC-DMIS has an option to automatically save a program between the operator pressing the "play" button and the start of the run. Why does this feature (which I've never found useful but hey, it doesn't hurt) exist but not one that automatically saves at the *end* of the run? You know, *after* generating all the valuable data?

I can't be the only person on the planet where PC-DMIS sometimes crashes after an overnight run. This just happened (again) last night and a 5h 49m lights-out run was wiped out! It crashed so hard it doesn't even know it crashed; no error report was generated!

If you can't fix the problem can you at least make a workaround?

Сервис поддержки клиентов работает на платформе UserEcho