Hexagon Measurement SystemsNo matter what Hexagon measurement equipment or software you use, we want to hear your ideas and suggestions on how we can improve.

Thanks for your assistance in helping us shape the future. |

|

Show 3D Grid in Graphic Window(Polar)

Show 3D Grid in Graphic Window(Polar)

I would like to see a polar representation of the Show 3D Grid in Graphic Window , the Cartesian works great when you need a visual representation of location in an XY or what ever plane view you might be in. Allowing users to see the Polar version would help when utilizing a rotary table therefore we can get a better designation of rotation when trying to figure out both hole patterns that are not equally spaced.

Infer qualification of multiple tips

Infer qualification of multiple tips

Qualify a small group of angles and use that data to preform the calculations for the rest instead of qualifying every angle individually.

Add: Curved profile to Flat plane intersection feature.

Add: Curved profile to Flat plane intersection feature.

I already talked with Hexagon support and they suggested I submit this idea, given it's not a feature available yet.

An intersecting line between two flat planes is easy but there's currently no option for curved profile to flat plane intersection option.

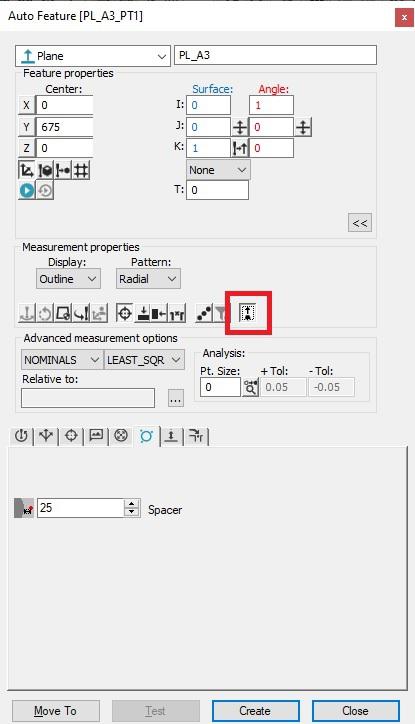

Change name of the seperate point when using 'To points' in autofeature

Change name of the seperate point when using 'To points' in autofeature

When using the 'To points' option in an autofeature, you can give in the name of the plane. In this case 'PL_A3'.

When 'To points' is ticked and you press 'Create', then you will get seperate points with a constructed plane called 'PL_A3'.

The points are named like the last saved featurename for a point.

But I want them named 'PL_A3_PT1, 'PL_A3_PT2', etcetera.

At this moment I have to make a point and call it 'PL_A3_PT1' and make the ID default, and then delete it.

Is it possible that you get something like a popup in wich you can input the name of the first point?

And as a bonus, can you add in that popup the question if you want place the points in a group and what the name of that group should be.

Thanks.

Gr. Wesley.

Path lines controls

Path lines controls

I would like to see controls for path lines animations which can be changed during animations. This controls would be Play, Pause, Speed change + & -, how many last path lines can be seen (only 10, 20 or xx last path lines). Now it is hard to see new path lines when there are a lot of previous path lines.

Quick Fixture - Update with New Hardware

Quick Fixture - Update with New Hardware

Please update Quick Fixture and add some new hardware like the stuff from Phillips Precision(Inspection Arsenal), Rayco Fixture, Renishaw(R&R Fixture), and etc.

Also, it would be nice to have typical tools of the trade like 1-2-3 Block, 2-4-6 Block, V-Block, Vise, & etc inside of this feature also.

This feature is really helpful for offline programming to help aid operators trying to figure out a setup from programmers.

How to measure the angle of 170 degrees?

How to measure the angle of 170 degrees?

How to measure the angle of 170 degrees? straight sections on both sides lengthen. the bend is in the middle of the pipe configuration. Is it possible to measure the U-shaped bend?

GD&T Full blown version

GD&T Full blown version

GD&T capture is very impressive with Trupo callouts. Would like it to include everything from a print. Distance, Basic, Notes, Find numbers and Database Ballooning. Name the feature with the GD&T. Then output into AS9100 format Excel file.

Сервис поддержки клиентов работает на платформе UserEcho