Hexagon Measurement SystemsNo matter what Hexagon measurement equipment or software you use, we want to hear your ideas and suggestions on how we can improve.

Thanks for your assistance in helping us shape the future. |

|

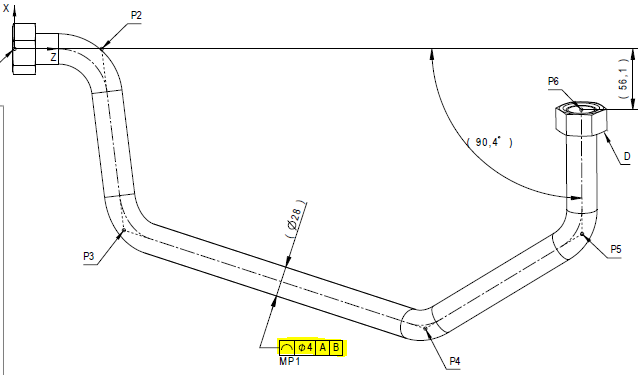

Add cylindrical line profile tolerance evaluation (for pipes/tubes)

Add cylindrical line profile tolerance evaluation (for pipes/tubes)

I would love to have the possibility to evaluate cylindrical line profile tolerances, especially used on tubes/pipes.

Example:

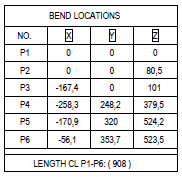

Often (but not always) used with a coordinate table:

...and a bending radii:

With this information, we can create a pipe centerline (if we don't have CAD) to use as nominal.

I have already checked the other Hexagon software offerings, such as BendingStudio and TubeShaper and they cannot evaluate this. The application manager for BS even told me that BS cannot and will not be able to evaluate this. BS is for manufacturing - not metrology.

AFAIK, no software on the market can evaluate this, except for PC-DMIS and Metrolog - with the help of an external program made by Hexagon Metrology Nordic called JoTube2. However, this program is no longer under active maintenance and hasn't been updated since 2013, probably due to low sales (and the author retired). This means that we need to find a solution to this problem as the software is slowly decaying due to OS upgrades and soon we won't have the luxury of being able to use it.

The two largest truck companies in Sweden are using this line profile tolerance for their pipes, I am unsure of other manufacturers. This means that the suppliers to them are suffering from the same problem - no proper evaluation method...

Line profile is mainly 2D, but ISO 1101 points to ISO 1660 that states that line profile tolerance zone can be made cylindrical by preceding the tolerance value with Ø.

Please consider to include this to PC-DMIS, either as an option or a standard feature!

Summary and command mode taskbar button

Summary and command mode taskbar button

Addition of a taskbar button to switch between summary and command mode easily

Separate scanning parameters from probing parameters

Separate scanning parameters from probing parameters

When changes are made to scan parameters such as point density

all other probe parameters are also automatically entered in the program.

However, if parts are measured with different measuring machines but the same program, the stored probe parameters must not be changed.

As this is not possible, the probe parameters must be adjusted each time in the program.

Scanning parameters should therefore be separated from the probe parameters, as is the case in other areas.

Visual indicator for scan control points

Visual indicator for scan control points

When trying to add control points it is very difficult to understand what the control point is actually doing or when it will trigger. If there could be some sort of visual aid that shows the control point along the scan path that would be very helpful.

Excel Form Report, PCD ID |x||y||z| output

Excel Form Report, PCD ID |x||y||z| output

In excel form report, can we implement where the xyz values will run in a row for a dimension, and than in the next row below it another dimension and it's xyz values, and so on and so forth.

Example:

Row1: |X|,|Y|,|Z|,|PCD ID|

Row2: |X|,|Y|,|Z|,|PCD ID|

Row3: |X|,|Y|,|Z|,|PCD ID|

etc.

Streamline Dimensioning

Streamline Dimensioning

I feel like a lot of features have been upgrade or streamlined to make them as easy or possible to use, but dimensioning has been left behind. For example if I have a lot of dimensions coming from Datum A I have to click on Datum A every time I want to Dimension from that. I know I could make that my zero then report the locations but some of our customers are very particular about cmm reports.

We should have an option to Keep datum A selected and only have to select what we want the dimension to go to. This would save some time and some clicking.

Thats the only idea I have for now but im sure other people have other ideas for this.

Locking a feature label to

Locking a feature label to

I would like to be able to select feature labels to stay in the view in the camera while dimensioning. For example if the part is really big but all the dimensions come from Datum A it would be nice to have the datum A feature label always in the camera view to easily select it. Right now can drag the label around but this would be much easier. The same way we can lock and unlock targets on the vision systems

Auto Close Program

Auto Close Program

The ability to add a line of code that would automatically file>close or file quit a program.

Similar to routine end.

Kundesupport af UserEcho