Hexagon Measurement SystemsNo matter what Hexagon measurement equipment or software you use, we want to hear your ideas and suggestions on how we can improve.

Thanks for your assistance in helping us shape the future. |

|

Mapped drives in win10

Mapped drives in win10

Dialog Save As or Open in win10 with 2018R1 doesn't work. PCDMIS doesn't see any network mapped drives or folder from Quick Access. Please fix that. because we cant work without that.

Give me more time to name a new probe file!

Give me more time to name a new probe file!

I'd like more time to type the name of a new probe file in Probe Utilities. After a few seconds (for indecisive/slow typists) you are bounced out of the Probe file field and into Probe description.

If you continue typing in the field after being bounced out of it, you will be asked if you want to save changes to the prior probe file (which is essentially nothing). This is confusing and frustrating to new users. Perhaps the time limit could be removed to allow the user more control.

Having said that, I have to give credit to the developers for the improvements to Probe Utilities in 2018 R2. I like what I'm seeing in the technical preview.

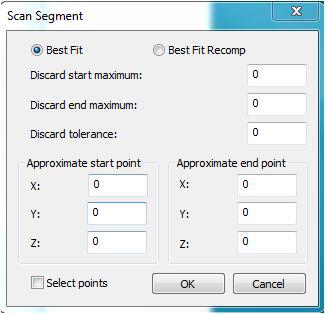

New possibility to construct a Scan-Segment from a Scan and Curve-Segment from a Scan

New possibility to construct a Scan-Segment from a Scan and Curve-Segment from a Scan

I need a possibility to construct a Scan-Segment from a Scan and Curve-Segment from a Scan in the Constructed Features “Feature Sets” and “Curves”.

This gives me the possibility to do different constructions, calculations and analyzes with the Segments.

If you scan for example a complete inner or outer contour like a cloverleaf or something else, it is not possible to split this complete Scan in Segments about a function like Scan Segment in the Circle and Line construction Dialog.

Actual you can just do it about the Hit Numbers programming [ ]. But this is dangerous, depend on, if you change for any reason the Point Density from the scan. Or you can just measure Segment with more as one Scan. This is not very niche for the runtime etc.

Make the Mini Routine Dialog readable from outside PC-DMIS

Make the Mini Routine Dialog readable from outside PC-DMIS

It would be nice if the Mini Routine Dialog readable for any Automation, for example Inspect.

If I wrote a Routine within Mini Routines, I expect, tat Inspect opens the Mini Routine Dialog to select the Mini Routine which I will execute, before the Routine will be opened and executed.

DIMENSIONING TOGGLE

DIMENSIONING TOGGLE

I suggest creating a toggle within auto features dialog box to turn on and off auto dimensions.

Playlist end of execution should show a summary containing all the measured items, not just the last

Playlist end of execution should show a summary containing all the measured items, not just the last

Seamless routines execution without summary screen confirmation after each routine.

Instead, one overall summary screen after playlist is executed.

Scale to fit when graphic views or rotation widget side is clicked on

Scale to fit when graphic views or rotation widget side is clicked on

When using the graphic views toolbar or clicking on the rotation widget sides, I'd like the cad to scale to fit to the graphics display window. If memory serves, this was the case back in 2011 but in subsequent releases has rotated the cad sometimes off the screen, sometimes ending up only showing part of the model on screen.

Saving all related objects

Saving all related objects

When I save down from a newer version I'd like all the related object in the routine to save down with it.

I use a lot of forms and report label templates so I'm constantly running from the production floor back to my desk to save each part of the puzzle down to the version running on that CMM..

I know what people are going to say, why not 1 version for everything.

We do our testing offline before migrating to the production machines.

And with 15 CMM's we can't always count on the newer versions working with a particular controller.

carry tolerances forward to like tolerances "warning"; one answer for equal bilateral zones

carry tolerances forward to like tolerances "warning"; one answer for equal bilateral zones

when editing the tolerances zones (+,-), and the zone is a bilateral equally disposed zone, have a setting where the warning message will then change the pos and neg allowance at one time, rather than having the message pop up for both the pos and neg tolerance. This can be accomplished currently by keying in the value and tabbing to the next value, however, there are times when using a ten-key pad and mouse, that this is not as user friendly (tenkey pad doesnt typically have a tab key on it).

Better report saving

Better report saving

save per serial number, date time was measured, default location,...

Customer support service by UserEcho