Hexagon Measurement SystemsNo matter what Hexagon measurement equipment or software you use, we want to hear your ideas and suggestions on how we can improve.

Thanks for your assistance in helping us shape the future. |

|

some terminology mistakes in Chinese version

some terminology mistakes in Chinese version

In the Chinese version, the following terminologies do not match the Chinese national standard:

| English terminologies Feature Plus Tolerence Minus Tolerance | Terminologies in Chinese PC-DMIS 特征 上公差 下公差 | Terminologies in GB 要素 上极限偏差 下极限偏差 |

How can i stop nexus metrology reporting every single time when one feature execute? any solution?

How can i stop nexus metrology reporting every single time when one feature execute? any solution?

PCDMIS admin panel

PCDMIS admin panel

Hello PCDMIS gurus and devs.

I would appreciate if PCDMIS had admin panel where I could define all settings once and then point this admin panel to every computer where installation of PCDMIS exists this way If I wanted to change say for example speed of all machines or some other generic settings it would be done from one panel. For example layout of buttons, speed of 3D CMM, loading colors for highlighting code etc.

Adding comment to assign command

Adding comment to assign command

You should be able to add a comment to the end of an assign line of code.

For example, currently the code is

ASSIGN/V1=10

it would be good if you could add a comment at the end to help with editing the program by adding $$ at the end, example

ASSIGN/V1=10 $$ diameter of hole 1

ASSIGN/V2=20 $$ diameter of hole 2

Implement support of a compound datum made of two non coaxial circles.

Implement support of a compound datum made of two non coaxial circles.

Example A is a plane, B and C are two circles laying in plane A. I need to evaluate GD&T relative to A|B-C. B-C should be treated a as pattern. ref case #00757938

Note: B and C are measured on a thin glass lens with a Vision probe on an Optiv Reference machine: they are 2D and cannot be measured as cylinders.

This functionality is supported in other metrology software. This is very frustrating and embarrassing for my customers.

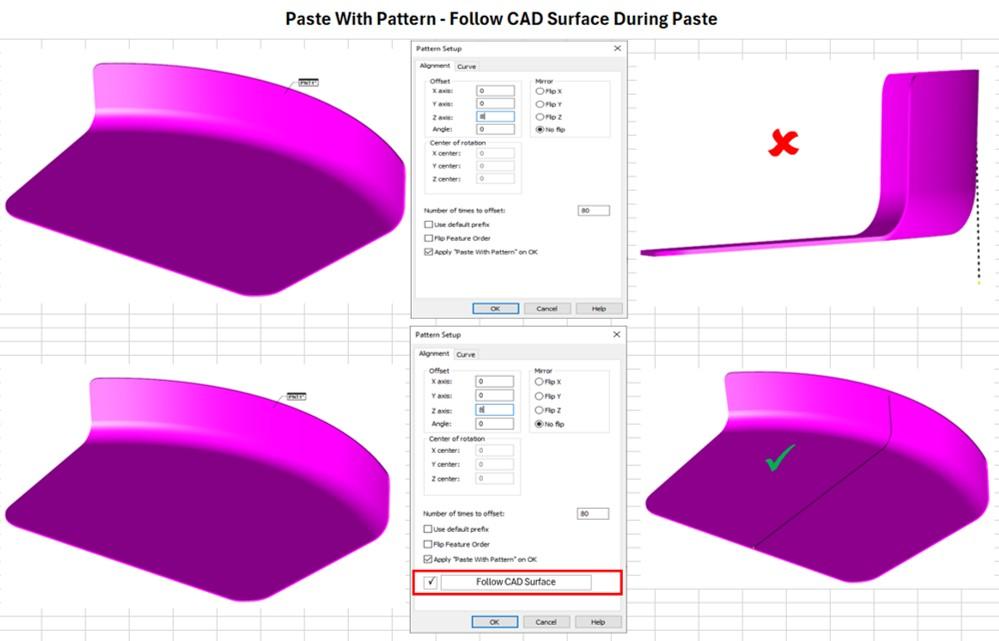

Paste with Pattern - Follow CAD Surface During Paste

Paste with Pattern - Follow CAD Surface During Paste

I would like the paste with pattern function to have the ability to follow the CAD nominals surface as it pastes. Currently paste with pattern only applies the pattern offsets to the copied point and does not necessarily follow CAD. This works fine for flat surfaces but does not work for any surface with shape. I understand that paste with pattern "Curve" follows CAD but only the edge curve. Paste with pattern that would follow the CAD surface would allow users to fill any surface with surface points by only programming one surface point. This would be a huge time saver and give the user the ability to put multiple points anywhere on the CAD surface quickly. With PC-DMIS portable the COP contains millions of points but it is time consuming if you wanted to add rows of surface points on surface with shape. This would be a good feature for Portable or CMM.

Export part model and measured features/pointcloud in the same file.

Export part model and measured features/pointcloud in the same file.

I have run into multiple examples of engineers wanting to do their own analysis on the measured CMM data. At times it is difficult to align the part and points in the modeling software. I can export the data and the part model in separate files but not in the same file.

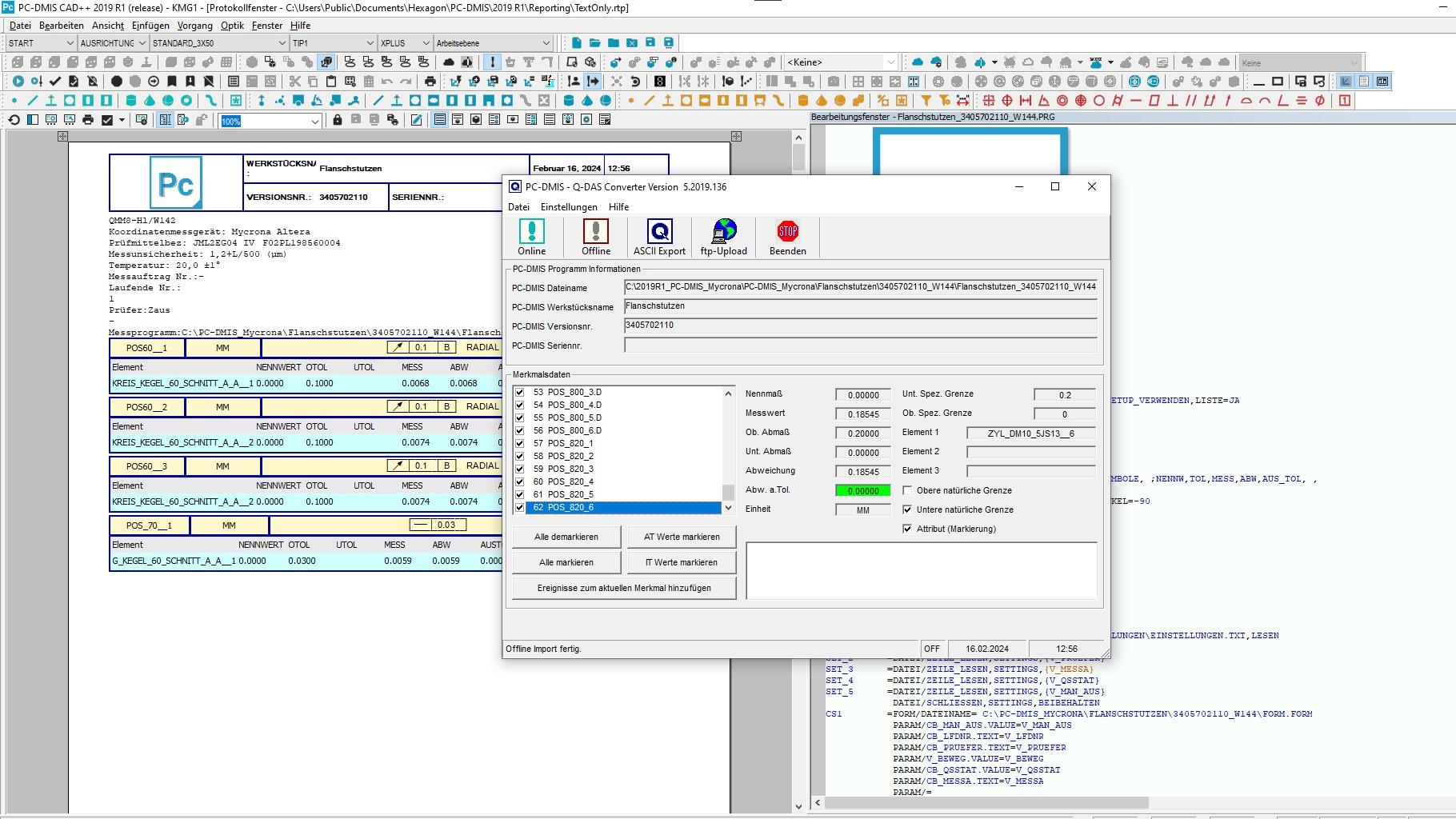

Q-Das Konverter manuelle Exportfunktion

Q-Das Konverter manuelle Exportfunktion

Beim alten externen Q-DAS Konverter konnten die Ergebnisse manuell exportiert werden mit dem Offline/ASCII Export Button.

Beim neuen integrierten Q-DAS Konverter können die Ergebnisse nicht mehr manuell exportiert werden.

Wäre von Vorteil wenn die Funktion auch im internen Q-DAS Konverter zur Verfügung stehen würde,

weil wenn n.i.O Merkmale nachgemessen werden, muss nicht die ganze Messroutine ausgeführt werden

Allow Edit/Graphics Window to snap to screen size.

Allow Edit/Graphics Window to snap to screen size.

Allow the Edit or Graphics CAD window to snap to Screen monitor (Like other programs in windows) so that CAD window can be viewed on one monitor and the edit window on the other without having to manually resize it it fit.

Servicio de atención al cliente por UserEcho