Hexagon Measurement SystemsNo matter what Hexagon measurement equipment or software you use, we want to hear your ideas and suggestions on how we can improve.

Thanks for your assistance in helping us shape the future. |

|

Remaining Travel + Next Action Display for CMM

Remaining Travel + Next Action Display for CMM

I suggest adding a “remaining travel” and “next action” display for the 3D CMM, similar to what we have on CNC lathes and milling machines. This would give a clear overview of where the machine will move next, helping to avoid collisions and making it easier to follow what happens during program runs or teaching.

Thanks for considering this! Edit: I accedentally suggested this on Hardware so I wanted to resuggest it here too.

Datum modifiers for perpendicularity if datums are features of size

Datum modifiers for perpendicularity if datums are features of size

PC-DMIS doesn't allow datum modifiers for perpendicularity on features of size. we see this a lot and would like to see this capability added on.

A possibility to Add "Tolerances" to colors (RGB) like in Hexagon VISI or maybe in a simpler way

A possibility to Add "Tolerances" to colors (RGB) like in Hexagon VISI or maybe in a simpler way

We work more and more with colors and PMI`s to reduce drawings to a minimum.

At the moment we are at the point, that we can handle RGB colors in our CAD, in the CAM and in the Viewer.

But in our quality department is it not possbile to work with colors in a fast way, because PC-DMIS shows only RGB codes of the Surfaces (Information Surface)

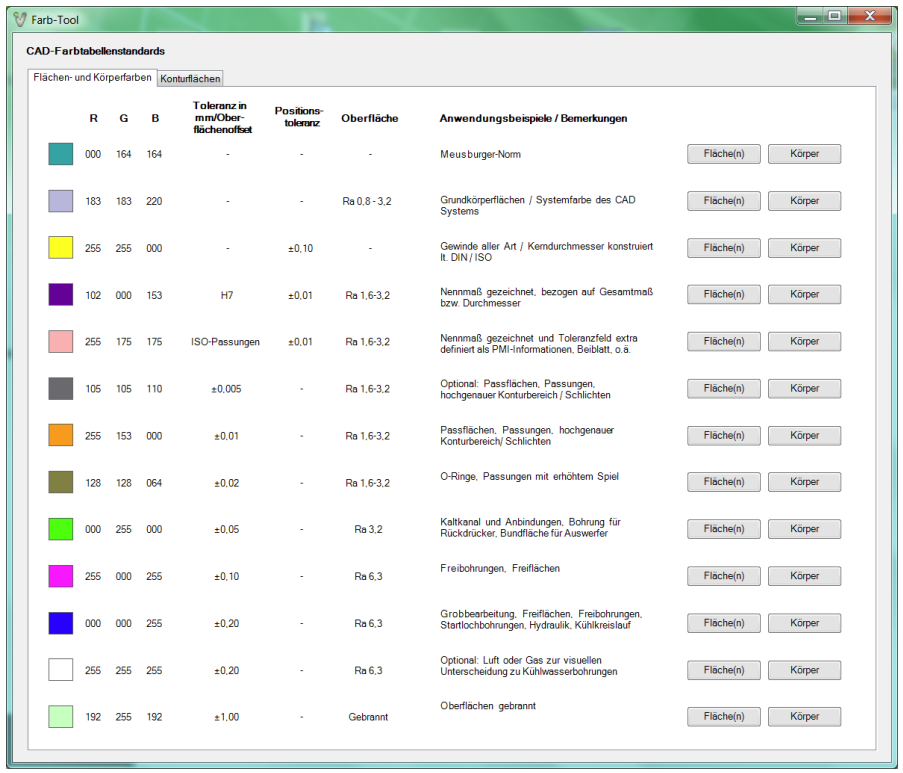

We would wish a to have a possibility to see a tolerance for every RGB color like in Hexagon VISI.

In our business field all companys work already with the similar color code. (Meusburger, VISI, Hasco, VDWF, ....)

Than you don`t need so much time to add PMI`s, because the colors are so much faster and you understand in few seconds the parts and what you have to measure.

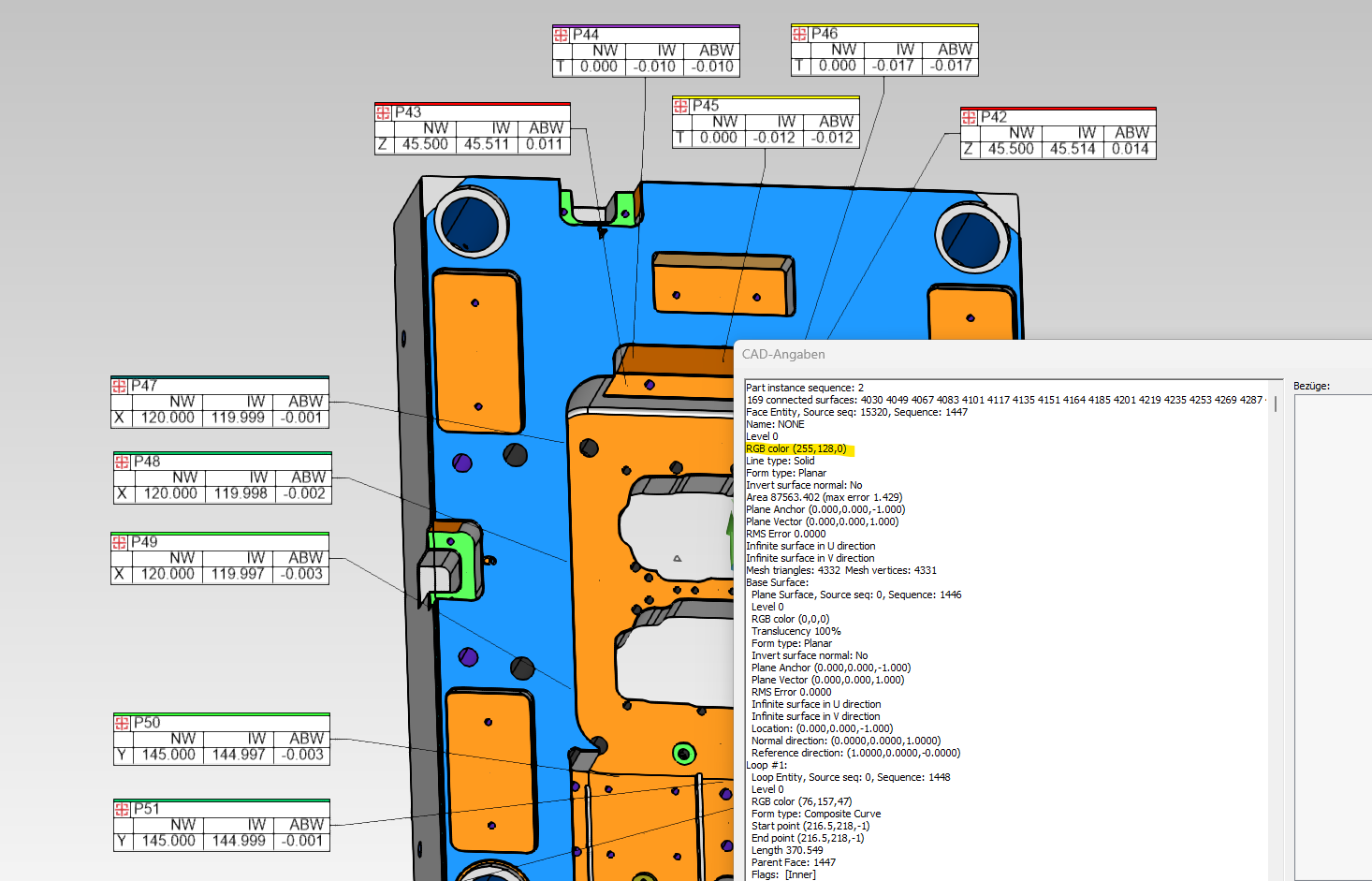

Example how you can at the moment see the color in PC-DMIS, but no Tolerance:

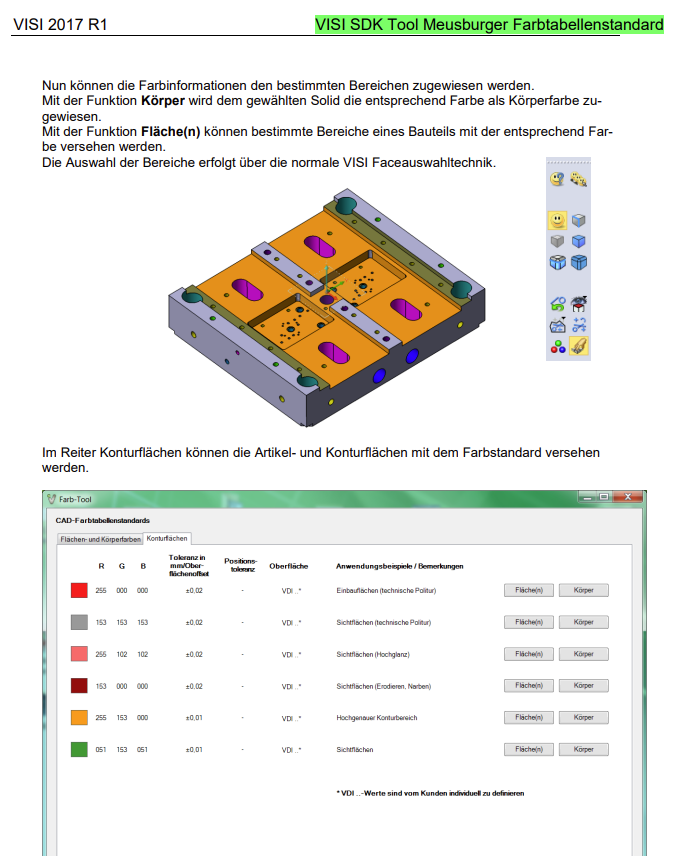

This is how you can see it in Hexagon Visi:

Pointcloud Operator (select funktion)

Pointcloud Operator (select funktion)

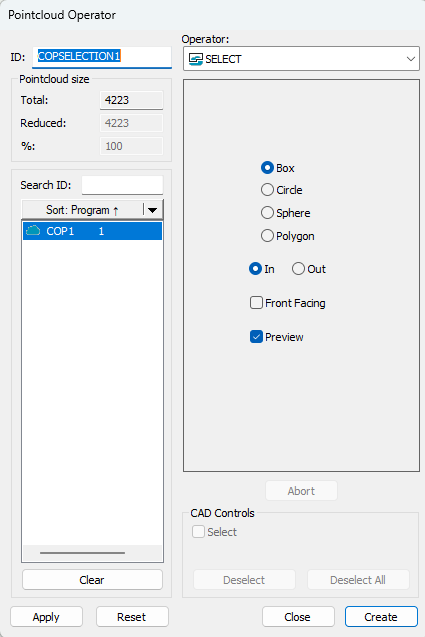

In select function menu I like to have a "multi select funktion".

So I don't need to reset the cloud every time I need several section.

Point cloud alignment

Point cloud alignment

Customers who manufacture plates for hydrogen fuel cells or heat exchangers usually want their tool halves to be aligned according to the following principle.

1. The tool is aligned with a probe.

2. Then it is scanned with a laser (HP-L-10.10)

3. A Refine alignment is performed with the point cloud.

4. A primary plane is extracted from the point cloud.

5. Aligns as Z primary and Z zero.

6. Evaluates

However, this procedure is not correct as the plane is not exactly parallel to the pattern!

Of course, you can extract points and use these for XY and Z rotation, or construct "alignment features", but I want to use all the points in the pattern area in a easy way.

What I want is more possibilities in the point cloud alignment so that I can control/adjust my alignment better.

Create a public API for automation of Inspect

Create a public API for automation of Inspect

Would like to have the ability to integrate external applications using Inspect API for process automations similar to what's available in PC-DMIS API options.

Improving Program Traceability in PC-DMIS: Folder-Based Saving Strategy Inspired by PolyWorks

Improving Program Traceability in PC-DMIS: Folder-Based Saving Strategy Inspired by PolyWorks

It would be a good idea to configure PC-DMIS so that each measurement program is automatically saved in its designated folder. This improves traceability and makes it easier to retrieve previous measurement sessions for review or verification. For example, if I need to revisit a measurement I performed a few days ago, I can quickly locate the corresponding program and results.

Technically, this can be achieved by setting a default save path in PC-DMIS, either through the software preferences or by using a startup script. This ensures that all programs are stored in a structured and consistent way, reducing the risk of file misplacement or overwriting. It also supports better version control and simplifies data management, especially in multi-user environments.

This kind of functionality already exists in PolyWorks, where the software automatically organizes measurement projects into predefined folders, making it easier to manage and access historical data. Implementing a similar approach in PC-DMIS would bring significant benefits to workflow efficiency and data integrity.

Add function to AUTO CYLINDERS

Add function to AUTO CYLINDERS

add ability to AUTO CYLINDER to generate TO CIRCLES similar to TO POINTS

Carry Like Tolerances Forward

Carry Like Tolerances Forward

There was a time of programming when I was asked to "Carry Like Tolerances Forward" and I clicked on "Don't ask me again" and since then, I haven't been. There have been multiple occasions since where that feature would be useful but I don't know how to get it back for new programs...

Service d'assistance aux clients par UserEcho