Hexagon Measurement SystemsNo matter what Hexagon measurement equipment or software you use, we want to hear your ideas and suggestions on how we can improve.

Thanks for your assistance in helping us shape the future. |

|

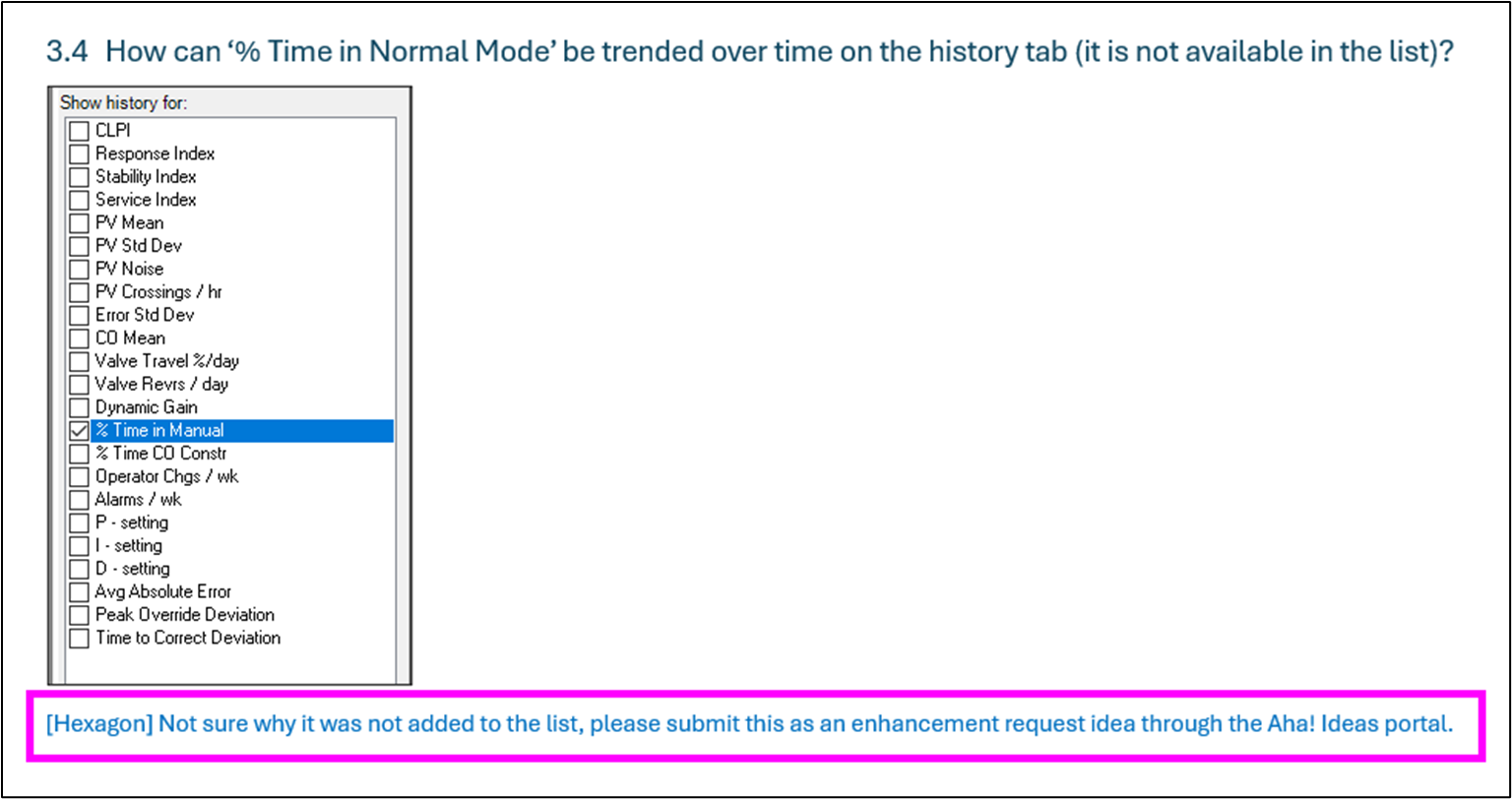

In ControlWizard Assessment History Add The Ability To Trend ‘% Time in Normal Mode’

In ControlWizard Assessment History Add The Ability To Trend ‘% Time in Normal Mode’

As per the header.

Raising this enhancement at the suggestion of HAMZAH Abd Aziz (Aziz) <abd.aziz.hamzah@hexagon.com> in response to my question, refer to email correspondence on 08-Oct-2025.

Create a public API for automation of Inspect

Create a public API for automation of Inspect

Would like to have the ability to integrate external applications using Inspect API for process automations similar to what's available in PC-DMIS API options.

Improving Program Traceability in PC-DMIS: Folder-Based Saving Strategy Inspired by PolyWorks

Improving Program Traceability in PC-DMIS: Folder-Based Saving Strategy Inspired by PolyWorks

It would be a good idea to configure PC-DMIS so that each measurement program is automatically saved in its designated folder. This improves traceability and makes it easier to retrieve previous measurement sessions for review or verification. For example, if I need to revisit a measurement I performed a few days ago, I can quickly locate the corresponding program and results.

Technically, this can be achieved by setting a default save path in PC-DMIS, either through the software preferences or by using a startup script. This ensures that all programs are stored in a structured and consistent way, reducing the risk of file misplacement or overwriting. It also supports better version control and simplifies data management, especially in multi-user environments.

This kind of functionality already exists in PolyWorks, where the software automatically organizes measurement projects into predefined folders, making it easier to manage and access historical data. Implementing a similar approach in PC-DMIS would bring significant benefits to workflow efficiency and data integrity.

Add function to AUTO CYLINDERS

Add function to AUTO CYLINDERS

add ability to AUTO CYLINDER to generate TO CIRCLES similar to TO POINTS

Carry Like Tolerances Forward

Carry Like Tolerances Forward

There was a time of programming when I was asked to "Carry Like Tolerances Forward" and I clicked on "Don't ask me again" and since then, I haven't been. There have been multiple occasions since where that feature would be useful but I don't know how to get it back for new programs...

Change the toolbar/user configuration files to something readable

Change the toolbar/user configuration files to something readable

Like title.

I would really like to have the toolbar/user configuration files (toolbar.dat, gbarstate.dat, et al.) to something user readable.

Like XML or JSON. When we "move" the old configuration files between versions/upgrades sometimes they end up with duplicate menu items, sometimes missing a menu item...

Today, there isn't a possibility for the user to add/edit the .dat files. This is possible with XML/JSON so the user can "see" if there is a menu item missing/duplicate. The only thing left to do is to delete the files and start over with setting up the GUI in PC-DMIS, which I find quite cumbersome.

Input comment text size setting, especially when using full screen input comments

Input comment text size setting, especially when using full screen input comments

I'm currently developing Pc-Dmis programs to be used in production. We typically have operators that run parts on up to 4 cmms each - they're performing setup (no manual measurements), loading parts, following prompts and printing reports only. We utilize bar code / 2d matrix scanners, and when the operators have to enter data into an input comment either manually or with a scanner they cannot easily see the text that has been entered. We use full screen input boxes for user input. I do have some programs that have forms, but I am currently the only programmer at our facility that knows how to create them. Would it be possible to add a text size control (full formatting would be awesome, just like on the forum I'm using now) to input/comment dialog boxes?

Point density via count vs per mm/in

Point density via count vs per mm/in

The ability to simply plug in the amount of points i want for a strategy vs amount of pts/mm would be useful as to not plug in a number that bogs the software into eternity.

Slot Point Distribution

Slot Point Distribution

It would be good to be able to measure hits along the flats of a round-ended slot, instead of being restricted to the radii on the ends of the slot.

Servicio de atención al cliente por UserEcho